What are the meanings of non-standard automated production lines? What are the advantages? Trusted friends who know non-standard automation know that non-standard automated production lines are simply non-standard automated equipment production lines in the production industry that are all user-generated, user-generated It is the only automatic system integration equipment that is not currently circulating in the market. It is assembled by unit equipment manufactured according to the common working norms and specifications promulgated by the state. It is based on the customer's use requirements. The following non-standard automatic machinery equipment manufacturers Xiaobian introduces to everyone:

First, different types of customers have different process requirements.

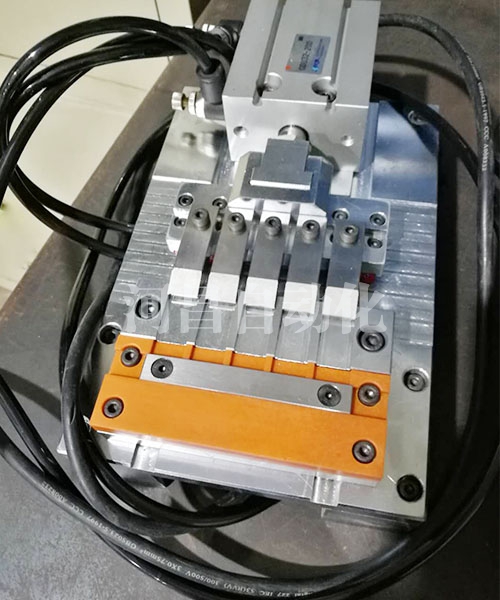

Non-standard automation equipment

Classification of non-standard automated production lines:

The classification is rather confusing. The main classification is based on the customer's work. There are generally the following elements: non-standard belt line series; non-standard double speed chain series; non-standard chain line series; non-standard roller line series; non-standard baking Main line series; non-standard equipment line series; non-standard automatic plane series. Non-standard VCM assembly machine production series production: the production is not as simple as the production of the standard equipment, the production of the standard equipment can be finished according to the specific rules according to the process. Non-standard equipment needs to be independently planned according to the specific application site, work characteristics, and use. The planning of non-standard equipment has no specific reference type.

Application: Non-standard automation equipment has a wide range of applications due to its wide range of products.

Second, the main applications are:

1. Auto parts and equipment for automobile production work;

2. Production, transportation and packaging of food work;

3. Delivery of electronic and electrical production line products;

4. There are also extensive applications in the storage equipment for logistics work;

5. The use of equipment work.

Third, maintenance specifications:

1. According to the application of equipment, clarify the reasonable maintenance quota and advance the technical level of maintenance;

2. Check if the temperature transmitter and the receiving line are loose or falling;

3. Check if the temperature transmitter has moisture and water ingress;

4. Check the calibration.

Suzhou Hechang Automation Technology Co., Ltd. is located in Chengdong Qingfeng Industrial Park, Wuzhi District, Wuzhong District, Suzhou. It is a professional non-standard automated processing assembly equipment and precision measuring equipment. Mainly cooperate with customers in the product processing industry automation equipment, product assembly, test automation equipment, testing (size, appearance) automation equipment, special inspection and fixture tooling and other aspects of customized development and manufacturing. Service Hotline: 86-512-66196533 Website: bigyu07.cn

86-512-66196533

Address: Chengdong Qingfeng Industrial Park, Wuzhi Town, Wuzhong District, Suzhou

Phone: 151-1912-8-8508

Website: bigyu07.cn